Products

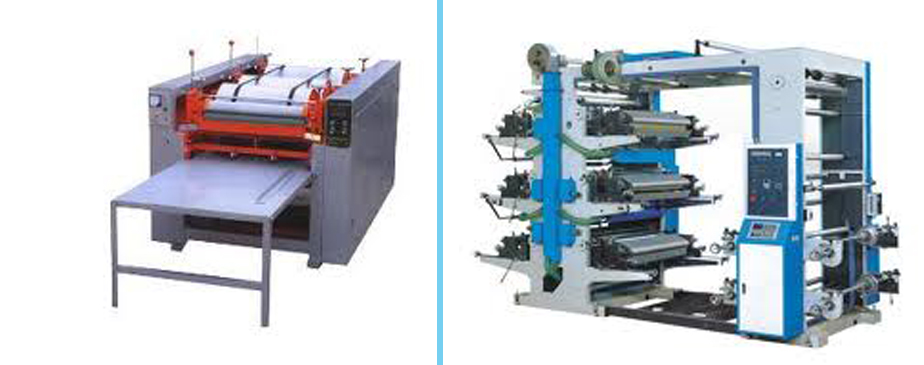

NON woven bag making machine with online box bag creasing unit

Unit |

Specification |

Model and origin |

Mainly Technical Parameter | Type | SSA-B600 / SSA-B700 /SSA-B800 |

Roller width | 50-1260mm/50-1460mm/50-1660mm |

|

Bag making speed | 20-100pcs/min(flat bag,rope bag)/20-70pcs/min(vest,box bag) |

|

Bag making width | 200-580mm |

|

Bag making length | random |

|

Bag specification | 20- 120g |

|

Power supply |

220v/330v |

|

Total power |

10.0kw |

|

Overall size(L*W*H) |

8500*1700*2000mm/ 8500*1900*2000mm/8500*2100*2000mm |

|

Mainly machine | Blanking unit | one set |

Horizontal traction unit |

one set |

|

Vertical fold unit |

one set |

|

Roller unit | Blanking way | magnetic powder tension controller |

Roller control device |

φ3"(φ76mm)Air Shaft |

|

Roller diameter |

φ1000mm |

|

Controller and Roller system | Roller control device | φ"(φ76mm)Air Shaft |

Correcting deviation device |

Automatic correcting deviation system(EPC) |

|

Automatic shutdown system |

Photoelectric eye |

|

Plate |

Stainless steel |

|

Power control system |

Special motor tension driver system |

|

Ultrasonic system |

7sets /8sets/8sets (the front ultrasonics from JinRong) |

|

Temperature control system |

Domestic Temperature control unit |

|

Operation |

man-machine interface touch control |

|

Relay |

Schneider omron from Japan |

|

Pneumatic component |

Sunris Taiwan |

|

Temperature gauge | Shanghai |

|

Switch |

Schneider Germany |

|

Inverter |

Dovol Taizhou |

|

converter motor |

Lichao Shanghai |

|

Touch Screen(PLC) |

Weinview Taiwan |

|

Final Products |

This machine can produce some different kind’s non woven bag .Such as handle bag, flat bag, rope bag. |

|

Attachment list |

Switch 8 pcs;synchronous belt 3pcs;approach switch 2pcs;spring 30pcs;relay 2pcs;tool box 1 set; electronic valve 3 pcs;grease gun 1 pcs; |

Introduction:

This is a Multifunctional nonwoven fabric bag making machine, whole machine can produce soft nonwoven fabric packing, such as nonwoven T-shirt bag, flat bag, handle bag, shoes bag etc. it is an ideal and effective bag making equipment.

Performance and Characteristics:

This machine is electro-mechanical integrative, once-through fully automatic forming, touch screen operation is applied, photo-electric trace, computerized deviation rectifying function, hence accuracy and smooth. Such automatic devices as slotting device, punching device and metering device are equipped. Finished products are produced at fast speed, in high efficiency, and in firm appearance after welding. This machinery is an optical choice for the nonwoven bag making enterprise and businessmen devoted to the production of nonwoven environment-friendly bags.

1) Local touch-screen computer configured to operate;2) Arbitrarily set a long-step electric track, a smooth, lost support from the standard parking

3) Feed off automatic shutdown, auto-punch;

4) While at the end of the roll-ultrasonic welding, in particular, solid, smooth;

5) Automatic temperature and automatically correcting leaks;

6) While cutting edge automatic closure, automatic nesting.

7) It is suitable for making Non-woven vest (T-shirt)bag, Non-woven flat bag, Non-woven handle bag , Non-woven rope(shoes) bag etc. (Add puncher for vest bag, handle making and welding bag machine for handle bag).

GO TO THE TOP

NON woven Die punching machine

DIE PUNCHING MACHINE

Feature: It is mainly used for the forming cutting of woven fabric, Non woven fabric,plastic,hdpe bags, paper, artificial leather and some textile material .It is featured by its flexibility, convenience and speed.

PARMETERS

Pressure : 8T

Stroke : 50mm

Working area : 620X350mm

Pressing plate size : 330X350mm

Power : 1.5hp

N.W. : 500kg

Dimension : 620X750X1600mm

Package size : 720X850X1650mm

Oil : 36kg

GO TO THE TOP

NON woven Handle fixing machine

This machine adopts PLC control, screen touch to operate, cool cutting with smoothness edge. Use high-frequency ultrasonic heat-sealing.

Model : SSABag width : 250mm-600mm

Speed : 18pcs/min

Thickness : 0.18mm-0.25mm

Power : Ø2kw

Overall size : L1650mmX W1560mmX H1240mm

GO TO THE TOP

NON woven Ultra sonic sewing machine

The principal and main technical index

Basic Principle

Figure 1 is the schematic drawing of CC serial ultrasonic lace sewing machine, which consists of:(1) ultrasonic generator ;

2) π/2 Ultrasonic energy converter ,

(3) π/2 (half-wave)variation lever;

(4) π/2 ultrasonic(half-wave) tool head ;

(5) pattern wheel

(6) motor, driving belt

(7) speed governor (1),motor(1);

(8) speed governor(2),motor(2);

(9)connection screws and some driving parts.

The ultrasonic generator can apply its energy upon the energy converter to create longitudinal mechanical Vibration, which can then be amplified by the tool head and the variation lever ,and form even and strong ultrasonic wave on the plane of the tool head (that is welding head).

The rotation of the tool head (welding head ) and the pattern mould are driven by two sets of speed –adjustable motor .when the pattern mould is pressed down ,it contacts the working surface of the tool head (welding head) and makes processes such as cutting, punching, sewing and melting on the fabric between the pattern mould and the working surface of the tool head (be care of pure cotton or slick fabric which could not be melted due to that they have no property what thermoplastic material has ).

The fabric is then brought away from the working table by the press wheel so that continuous processing can be carried out.

GO TO THE TOP

NON woven plane bag making machine

Unit |

Specification |

Model and origin |

Mainly Technical Parameter | Type | A600-800 |

Roller width | 50-1260mm |

|

Bag making speed | 20-100pcs/min |

|

Bag width | 200-600mm |

|

Bag length | random |

|

Bag specification | 20- 120g |

|

Power supply |

220v |

|

Total power |

10.0kw |

|

Overall size |

L7500*W1700*H2000mm |

|

Power supply |

220v |

|

Mainly machine | Blanking unit | one set |

Horizontal traction unit |

one set |

|

Vertical fold unit |

one set |

|

Roller unit | Blanking way | magnetic powder tension controller |

Roller control device |

φ3"(φ76mm)Air Shaft |

|

Roller diameter |

φ1000mm |

|

Controller and Roller system | Roller control device | φ"(φ76mm)Air Shaft |

Correcting deviation device |

Automatic correcting deviation system(EPC) |

|

Automatic shutdown system |

Photoelectric eye |

|

Plate |

Stainless steel |

|

Power control system |

Special motor tension driver system |

|

Ultrasonic system |

7 Set Athena Changzhou (better than Jinlong Xiamen) |

|

Temperature control system |

Domestic Temperature control unit |

|

Operation |

man-machine interface touch control |

|

Relay |

Schneider omron from Japan |

|

Pneumatic component |

Sunris Taiwan |

|

Temperature gauge | Shanghai |

|

Switch |

Schneider Germany |

|

Inverter |

Dovol Taizhou |

|

converter motor |

Lichao Shanghai |

|

Touch Screen(PLC) |

Weinview Taiwan |

|

Final Products |

This machine can produce some different kind’s non woven bag from 20 to 100g .Such as handle bag, flat bag, rope bag. |

|

Attachment list |

Switch 8 pcs;synchronous belt 3pcs;approach switch 2pcs;spring 30pcs;relay 2pcs;tool box 1 set; electronic valve 3 pcs;grease gun 1 pcs; |

GO TO THE TOP

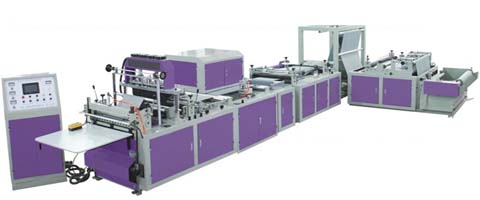

NON woven box bag making machine

Unit |

Specification |

Model and origin |

Mainly Technical Parameter | Type | SSA-B600 / SSA-B700 /SSA-B800 |

Roller width | 50-1260mm/50-1460mm/50-1660mm |

|

Bag making speed | 20-100pcs/min(flat bag,rope bag)/20-70pcs/min(vest,box bag) |

|

Bag making width | 200-580mm |

|

Bag making length | random |

|

Bag specification | 20- 120g |

|

Power supply |

220v/330v |

|

Total power |

10.0kw |

|

Overall size(L*W*H) |

8500*1700*2000mm/ 8500*1900*2000mm/8500*2100*2000mm |

|

Mainly machine | Blanking unit | one set |

Horizontal traction unit |

one set |

|

Vertical fold unit |

one set |

|

Roller unit | Blanking way | magnetic powder tension controller |

Roller control device |

φ3"(φ76mm)Air Shaft |

|

Roller diameter |

φ1000mm |

|

Controller and Roller system | Roller control device | φ"(φ76mm)Air Shaft |

Correcting deviation device |

Automatic correcting deviation system(EPC) |

|

Automatic shutdown system |

Photoelectric eye |

|

Plate |

Stainless steel |

|

Power control system |

Special motor tension driver system |

|

Ultrasonic system |

7sets /8sets/8sets (the front ultrasonics from JinRong) |

|

Temperature control system |

Domestic Temperature control unit |

|

Operation |

man-machine interface touch control |

|

Relay |

Schneider omron from Japan |

|

Pneumatic component |

Sunris Taiwan |

|

Temperature gauge | Shanghai |

|

Switch |

Schneider Germany |

|

Inverter |

Dovol Taizhou |

|

converter motor |

Lichao Shanghai |

|

Touch Screen(PLC) |

Weinview Taiwan |

|

Final Products |

This machine can produce some different kind’s non woven bag .Such as handle bag, flat bag, rope bag. |

|

Attachment list |

Switch 8 pcs;synchronous belt 3pcs;approach switch 2pcs;spring 30pcs;relay 2pcs;tool box 1 set; electronic valve 3 pcs;grease gun 1 pcs; |

Introduction:

This is a Multifunctional nonwoven fabric bag making machine, whole machine can produce soft nonwoven fabric packing, such as nonwoven T-shirt bag, flat bag, handle bag, shoes bag etc. it is an ideal and effective bag making equipment.

Performance and Characteristics:

This machine is electro-mechanical integrative, once-through fully automatic forming, touch screen operation is applied, photo-electric trace, computerized deviation rectifying function, hence accuracy and smooth. Such automatic devices as slotting device, punching device and metering device are equipped. Finished products are produced at fast speed, in high efficiency, and in firm appearance after welding. This machinery is an optical choice for the nonwoven bag making enterprise and businessmen devoted to the production of nonwoven environment-friendly bags.

1) Local touch-screen computer configured to operate;2) Arbitrarily set a long-step electric track, a smooth, lost support from the standard parking

3) Feed off automatic shutdown, auto-punch;

4) While at the end of the roll-ultrasonic welding, in particular, solid, smooth;

5) Automatic temperature and automatically correcting leaks;

6) While cutting edge automatic closure, automatic nesting.

7) It is suitable for making Non-woven vest (T-shirt)bag, Non-woven flat bag, Non-woven handle bag , Non-woven rope(shoes) bag etc. (Add puncher for vest bag, handle making and welding bag machine for handle bag).