Products

2 color bag to bag printing Machine

INFORMATION:

Automatic bag collecting machine can be matched

Product Description:

1) Meter counter equipped with pre-alarming bell.

2) 1500-3500p/h, stepless governor.

3) Imported PVC Transmission belt, antomatic positioning

4) Printing roller can be automatically tracing and separating

5) Oil leaking device can be replaced freely, oil-ink roller and offset can be separated and

harmonized.

6) Transferring oil-ink by roller moir, enhancing polished light for printing, saving oil-ink.

7) Rear transmission can be delayed with the function of airing

Main technology parameter:

Motor Power : 1.5KW (AC)Plate Making Thickness : 4-5mm

Working Members : 3Persons

Printing Speed : 1500-3500Pcs/hour

Max. Printing Area : 1200×640mm

Max.Material Feeding : 1300×850mm

GO TO THE TOP

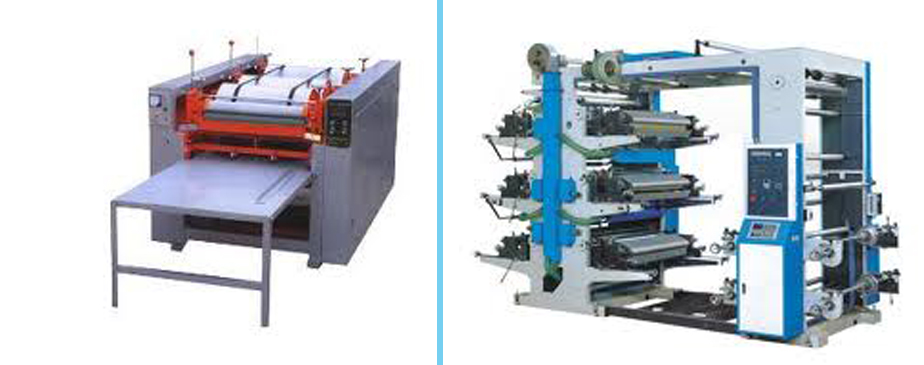

3 color bag to bag printing Machine

INFORMATION:

Automatic bag collecting machine can be matched

Product Description:

1) Meter counter equipped with pre-alarming bell.

2) 1500-3500p/h, stepless governor.

3) Imported PVC Transmission belt, antomatic positioning

4) Printing roller can be automatically tracing and separating

5) Oil leaking device can be replaced freely, oil-ink roller and offset can be separated and

harmonized.

6) Transferring oil-ink by roller moir, enhancing polished light for printing, saving oil-ink.

7) Rear transmission can be delayed with the function of airing

Main technology parameter:

Motor Power : 1.5KW (AC)Plate Making Thickness : 4-5mm

Working Members : 3Persons

Printing Speed : 1500-3500Pcs/hour

Max. Printing Area : 1200×640mm

Max.Material Feeding : 1300×850mm

GO TO THE TOP

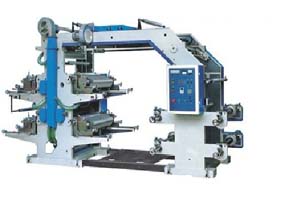

4 color bag to bag printing Machine

INFORMATION:

Automatic bag collecting machine can be matched

Product Description:

1) Meter counter equipped with pre-alarming bell.

2) 1500-3500p/h, stepless governor.

3) Imported PVC Transmission belt, antomatic positioning

4) Printing roller can be automatically tracing and separating

5) Oil leaking device can be replaced freely, oil-ink roller and offset can be separated and

harmonized.

6) Transferring oil-ink by roller moir, enhancing polished light for printing, saving oil-ink.

7) Rear transmission can be delayed with the function of airing

Main technology parameter:

Motor Power : 1.5KW (AC)Plate Making Thickness : 4-5mm

Working Members : 3Persons

Printing Speed : 1500-3500Pcs/hour

Max. Printing Area : 1200×640mm

Max.Material Feeding : 1300×850mm

GO TO THE TOP

2 color roll to roll printing Machine

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper non woven fabric, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1) Easy operation, flexible starting, accurate color register.

2) The meter counter can set printing quantity according to the

requirements. Stop the m achine automatically at the quantity or when

the material is cut off.

3) Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4) The printing ink is spread by the anilox cylinder with even ink color.

5) Reliable drying system coordinated with highspeed rotation, it will automatically break circuit when the machine stops.

6) 360°continuous and adjustable longitudinal register device.

7) The frequency control of motor speed adapts to different printing speeds.

8) There are Jogging/Stopping buttons on the plate roller base and

material rolling rack so as to make it easy operate the machine when the

plate is installed.

Max. Width of Printing Material : 1200mm

Max. Printing Width : 1160mm

Length Range of Printed Product : 191-914mm

Max. Diameter of Roll Material : Ø450mm

Printing Speed : 5-50m/min

Thickness of plate (Including two-sided Glue Paper) : 2.38mm

Total Power : 20kw

Weight of Machine : 8000kg

Overall Dimensions (mm) : 4200mmX2200mmX2400mm

GO TO THE TOP

3 color roll to roll printing Machine

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper non woven fabric, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1) Easy operation, flexible starting, accurate color register.

2) The meter counter can set printing quantity according to the

requirements. Stop the m achine automatically at the quantity or when

the material is cut off.

3) Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4) The printing ink is spread by the anilox cylinder with even ink color.

5) Reliable drying system coordinated with highspeed rotation, it will automatically break circuit when the machine stops.

6) 360°continuous and adjustable longitudinal register device.

7) The frequency control of motor speed adapts to different printing speeds.

8) There are Jogging/Stopping buttons on the plate roller base and

material rolling rack so as to make it easy operate the machine when the

plate is installed.

Max. Width of Printing Material : 1200mm

Max. Printing Width : 1160mm

Length Range of Printed Product : 191-914mm

Max. Diameter of Roll Material : Ø450mm

Printing Speed : 5-50m/min

Thickness of plate (Including two-sided Glue Paper) : 2.38mm

Total Power : 20kw

Weight of Machine : 8000kg

Overall Dimensions (mm) : 4200mmX2200mmX2400mm

GO TO THE TOP

4 color roll to roll printing Machine

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper non woven fabric, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1) Easy operation, flexible starting, accurate color register.

2) The meter counter can set printing quantity according to the

requirements. Stop the m achine automatically at the quantity or when

the material is cut off.

3) Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4) The printing ink is spread by the anilox cylinder with even ink color.

5) Reliable drying system coordinated with highspeed rotation, it will automatically break circuit when the machine stops.

6) 360°continuous and adjustable longitudinal register device.

7) The frequency control of motor speed adapts to different printing speeds.

8) There are Jogging/Stopping buttons on the plate roller base and

material rolling rack so as to make it easy operate the machine when the

plate is installed.

Max. Width of Printing Material : 1200mm

Max. Printing Width : 1160mm

Length Range of Printed Product : 191-914mm

Max. Diameter of Roll Material : Ø450mm

Printing Speed : 5-50m/min

Thickness of plate (Including two-sided Glue Paper) : 2.38mm

Total Power : 20kw

Weight of Machine : 8000kg

Overall Dimensions (mm) : 4200mmX2200mmX2400mm

GO TO THE TOP

NON woven Flexo graphic printing Machine

Introduce Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper non woven fabric, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1) Easy operation, flexible starting, accurate color register.

2) The meter counter can set printing quantity according to the

requirements. Stop the m achine automatically at the quantity or when

the material is cut off.

3) Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4) The printing ink is spread by the anilox cylinder with even ink color.

5) Reliable drying system coordinated with highspeed rotation, it will automatically break circuit when the machine stops.

6) 360°continuous and adjustable longitudinal register device.

7) The frequency control of motor speed adapts to different printing speeds.

8) There are Jogging/Stopping buttons on the plate roller base and

material rolling rack so as to make it easy operate the machine when the

plate is installed.

Max. Width of Printing Material : 1200mm

Max. Printing Width : 1160mm

Length Range of Printed Product : 191-914mm

Max. Diameter of Roll Material : Ø450mm

Printing Speed : 5-50m/min

Thickness of plate (Including two-sided Glue Paper) : 2.38mm

Total Power : 20kw

Weight of Machine : 8000kg

Overall Dimensions (mm) : 4200mmX2200mmX2400mm

GO TO THE TOP

NON woven OFF set printing Machine

Introduce sensitization resin as flexible printing plate, suitable for printing such packing materials as polyethylene, polypropylene bag, cellophane and roll paper non woven fabric, etc. It is a kind of ideal printing equipment for producing paper packing bag for food, supermarket handbag, vest bag and clothes bag, etc.

Performance and Features:

1) Easy operation, flexible starting, accurate color register.

2) The meter counter can set printing quantity according to the

requirements. Stop the m achine automatically at the quantity or when

the material is cut off.

3) Pneumatic printing cylinder lift and lower, it will stir the printing ink automatically after lifting.

4) The printing ink is spread by the anilox cylinder with even ink color.

5) Reliable drying system coordinated with highspeed rotation, it will automatically break circuit when the machine stops.

6) 360°continuous and adjustable longitudinal register device.

7) The frequency control of motor speed adapts to different printing speeds.

8) There are Jogging/Stopping buttons on the plate roller base and

material rolling rack so as to make it easy operate the machine when the

plate is installed.

Max. Width of Printing Material : 1200mm

Max. Printing Width : 1160mm

Length Range of Printed Product : 191-914mm

Max. Diameter of Roll Material : Ø450mm

Printing Speed : 5-50m/min

Thickness of plate (Including two-sided Glue Paper) : 2.38mm

Total Power : 20kw

Weight of Machine : 8000kg

Overall Dimensions (mm) : 4200mmX2200mmX2400mm